Home > Company News > Automated Filling

Company News

Sales Manager:Daniel

Mobile Phone:86- 13802155833

E-mail:tjwhoking@163.com

QQ:490045876

SKYPE:antonio87455

WeChat:13802155833

WhatsApp: 86-13802155833

1. Paper Poly Block Bottom Bag

It is a 2 layer bag out of which one layer is laminated with PP outside, while the other with loose craft paper lining inside. This bag is similar to PP bags and has very high moisture resistance and strength. Printing of diverse colors is possible, further as an Ad Star Bags / Block Bottom Bag manufacturer in India, we offer customization options also.

2. BOPP Block Bottom Bag

This bag is designed with BOPP film outside and PP fabric inside, typically used for high-resolution printing required by clients for branding purposes.

Application: Cement, gypsum, lime, other building materials, also sometimes in food products, chemical industries, and agriculture.

Shape: Block bottom - Brick shape

Material: Coated woven PP fabric

Dimensions and color: Available in standardized and customizable form both

Type: Valve or open mouth

Printing: Flexographic or Rotogravure

Higher Strength: To ensure the strong sacks manufactured have almost zero burst age, we have a personal laboratory where the bags are passed through various tests of dropping, pressing, bending, and so on.

Maximum Protection: As high-quality woven polypropylene coated fabric is used it assures the product stored or shipped is delivered safely with the utmost protection.

Space Efficient: Because of its appropriate dimensioning and high stacking, it assists in arranging and utilizing the space during shipping.

Resists Water & Humidity: High humidity and rough handling is the first advantage a client looks for, and this bag satisfies the needs. Whether it is lying on wet ground or kept under heavy rain, it prevents water and humidity at its finest.

Environment-friendly

Valve bags with block bottom or flat bottom also called paste bottom bags, is the most popular packing bag in the world now. Through automatic filling equipment, the goods come into the bag from the valve at the top or the bottom, become brick shape after filled. Block Bottom Valve Bags can be made of pp woven, pp woven compound with craft paper/ PE.

The Ad*Star Sack can be produced either as a one-layer Block Bottom Valve Bag (V-BB) or as an open mouth bag with a block bottom without valve (OM-BB) and with or without micro-perforations.

Fabric Construction – Circular Pp Woven Fabric (no seams) or Flat PP Woven Fabric (back seam bags) Laminate Construction – PE coating or BOPP Film Fabric Colors – White, Clear, Beige, Blue, Green, Red, Yellow or customized Printing – Off-set print, Flexo print, gravure print. UV Stabilization – Available Packing – 5,000 Bags per Pallet Standard Features – No stitching, completely hot welding

Optional Features:

Printing Anti-slip Embossing Micropore

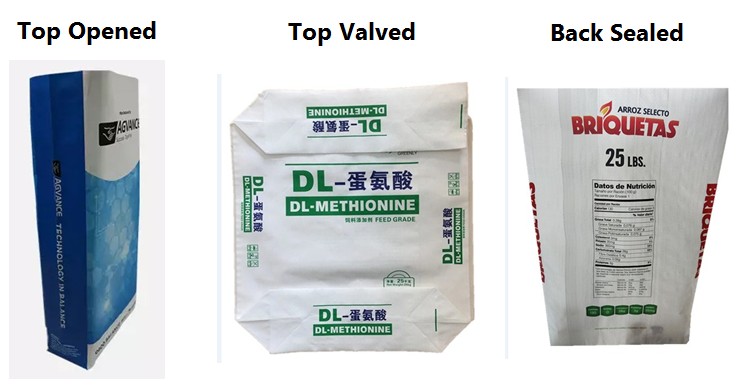

Valve extendable Kraft paper combinable Top opened or valved

Sizes Range:

Width: 350mm to 600mm

Length: 410mm to 910mm

Block width: 80-180mm

Weave: 6×6, 8×8, 10×10, 12×12, 14×14

Cost-effective

Recyclable and reusable

Non-fading printing